Activities

Mold design

The internal technical office has a long experience in the design of medium and large (12T) and multi-material (rotary molds) molds. The continuous refresher courses on CAD systems lead our team to constantly improve the design and, consequently, to improve and simplify the mechanical processing more and more trying to reduce the construction time of the mold. The customer is supported by a technician from the earliest stages of co-design, product engineering and the study of injection points. For some years now, the GARI design team has been carrying out the engineering of mechanical machining of mold components for third parties

.

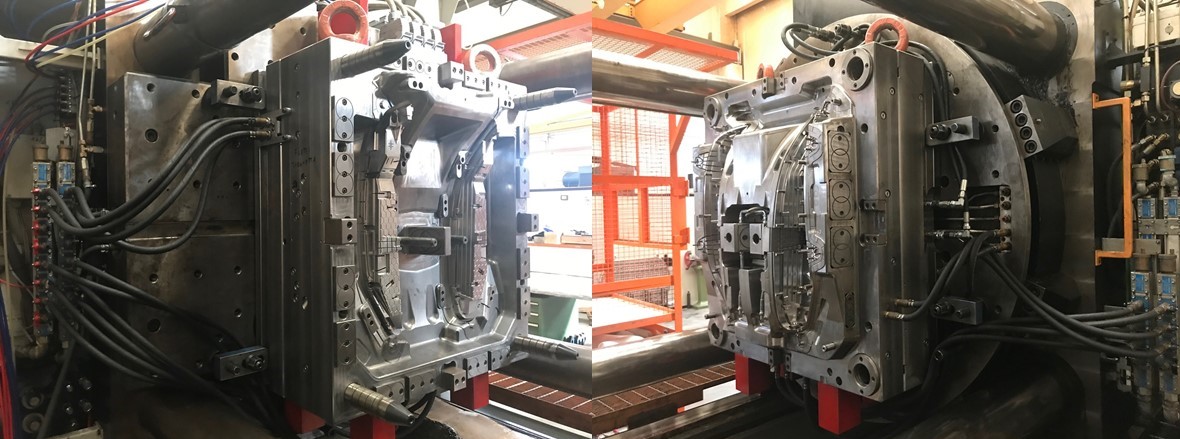

Mold construction

For over 40 years we have been building medium and large molds up to 12 Tons. The high precision achieved in the machining allows the construction of complex molds with a high aesthetic profile for the front and rear lighting components of the car. With the help of latest generation machinery and the constant updating of CAM systems, we have reached the maximum dimensional control of the semi-finished product in the production phase and a reduction in the recovery and polishing times of the mold thanks to the almost mirror-like finishes that modern machines offer.

Tool shop

The adjustment department is made up of 5 workstations equipped with the relative equipment for assembly and ultrasonic equipment for mirror polishing. Adjustments are carried out on all the components built inside us, and shelling of the eroded parts to facilitate the extraction of the pieces. Department equipped with a 12.5T double hook overhead crane for overturning the molds in total safety.

Injection machine

Since 2006 we have added an additional service for the customer with the inclusion of 1 injection molding machine of 480T and 1 injection molding machine of 1000T equipped with a rotary table and 4 injectors for rotary molds. In the final phase, the mold is put into the machine to perform a pre-testing series, during which the mechanics of the mold are tested; then, with the help of Cartesian robots for picking up the piece in the cycle, the cycle time required by the customer is guaranteed

Toll processing agreement

In addition to the construction of molds, we provide processing for third parties for deep drilling and ” zero ” milling of “figure” dowels and erosion of deep parts of medium and large molds. Thanks to the experience accumulated over the years, GARI puts its ability to process and manufacture complex high-precision mechanical components at the service of the market.